The Forced Induction Fallacy: When More Boost Masks Mediocrity

Enzo Ferrari said aerodynamics is for those who can't build engines. He should've added that turbocharging is a bandaid for weak engine designs.

Turbocharging has become the automotive industry’s favorite crutch; a way to squeeze impressive horsepower numbers from otherwise underwhelming engines while sidestepping the real challenge of building a fundamentally strong powerplant.

Manufacturers and tuners have embraced forced induction as a magic bullet, slapping turbos onto tiny, low-compression engines and calling it "efficiency" when, in reality, it’s just compensation for poor mechanical design.

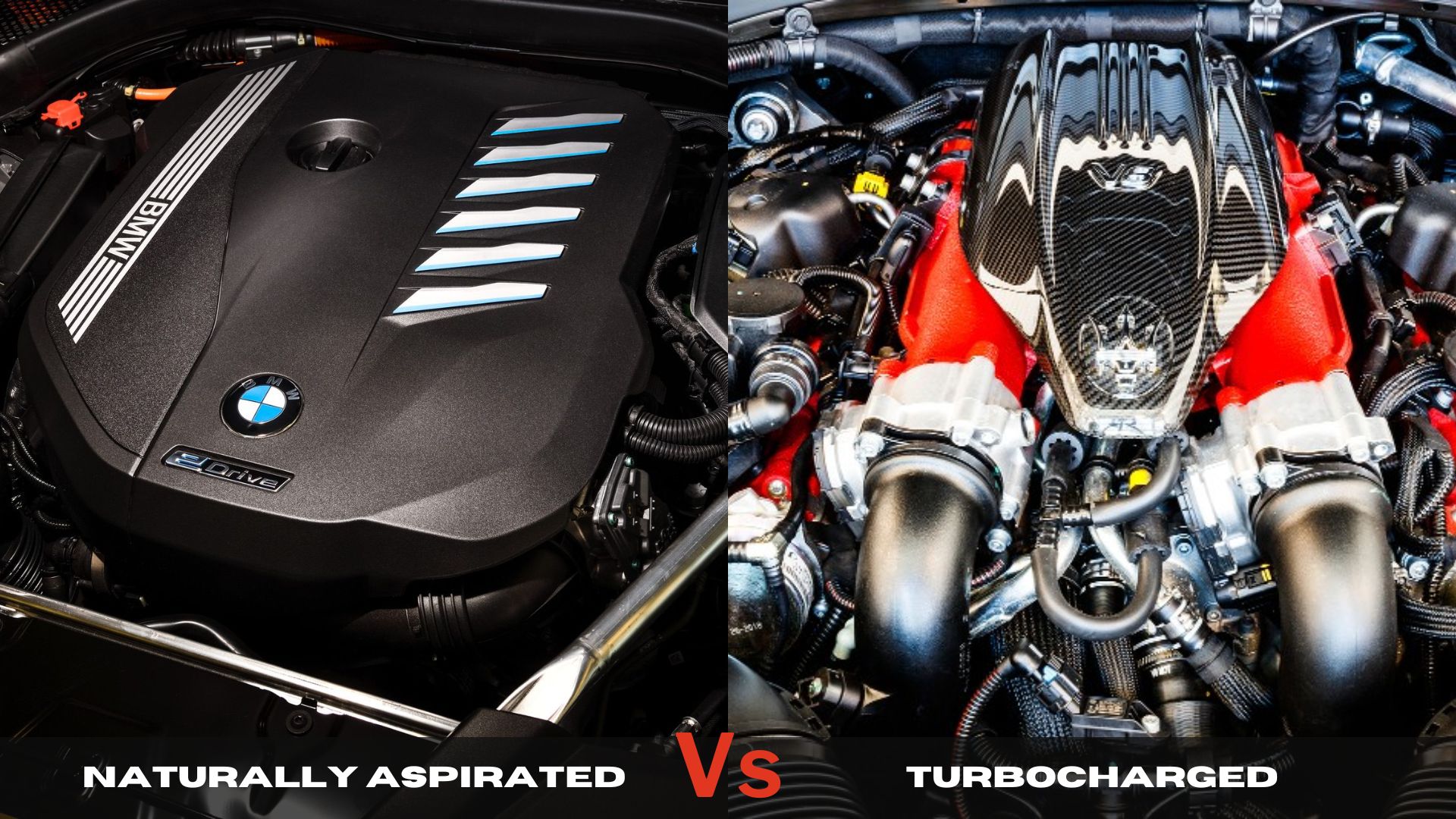

But let’s be clear: A turbocharged engine is not inherently better than a naturally aspirated one. In fact, the reliance on forced induction often exposes a lack of engineering ambition—a shortcut to power that sacrifices throttle response, longevity, and mechanical purity for the sake of bragging rights on a dyno sheet.

This isn’t just an old-school purist rant. This is a technical indictment of an industry that has forgotten how to build great engines without leaning on boost.

See also:

The Physics Of Power: Why NA Engines Are Objectively Superior

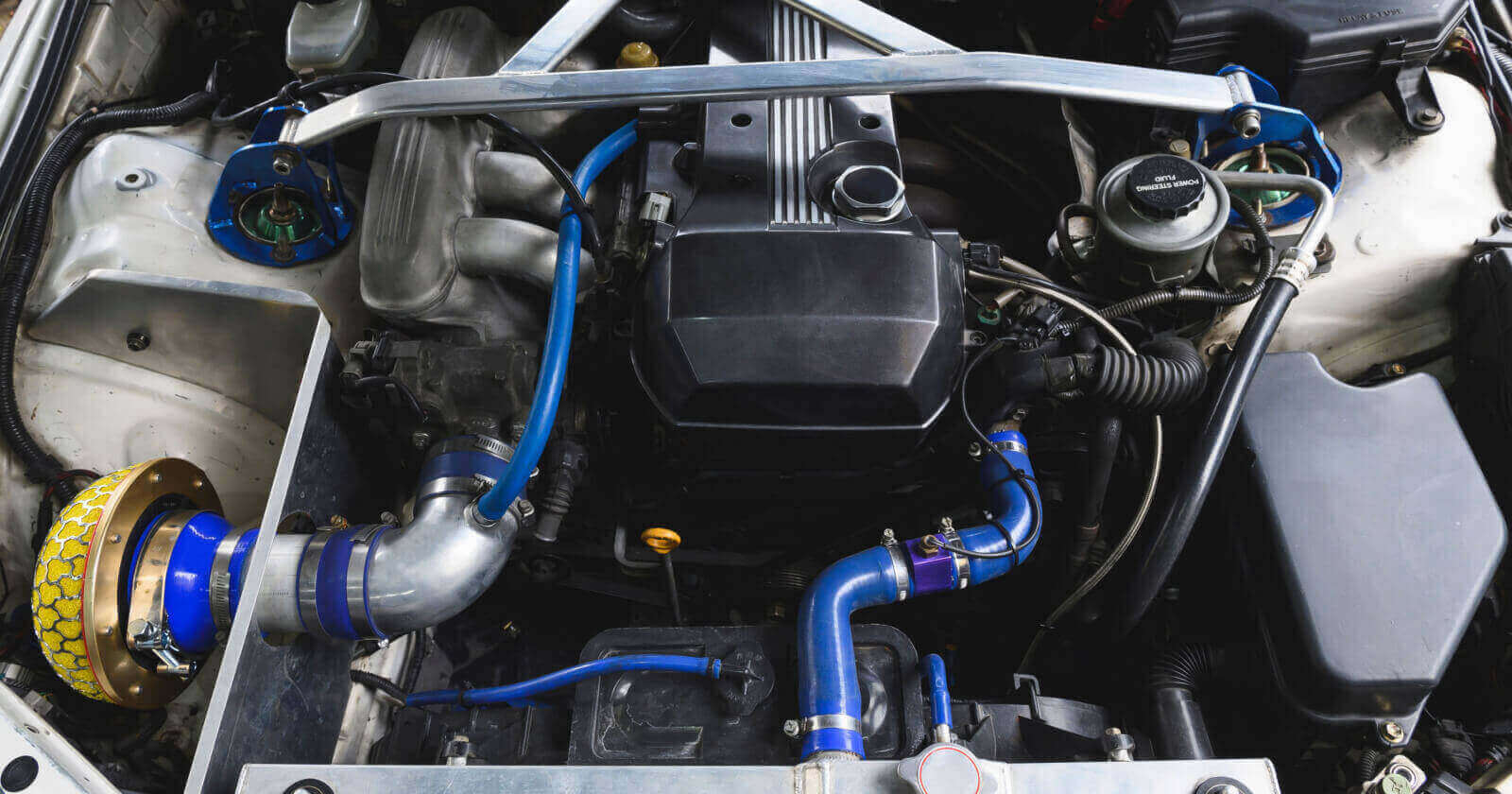

At its core, an internal combustion engine is an air pump. The more efficiently it breathes, the more power it makes. A naturally aspirated engine must do this on its own, through cam profiles, head flow, and displacement.

A turbocharged engine, by contrast, brute-forces air in under pressure, masking deficiencies in volumetric efficiency.

Consider the fundamental differences:

Throttle Response: A high-strung NA engine delivers instantaneous power because there’s no turbo lag, no waiting for spool. The connection between pedal and power is direct, unfiltered by the inertia of a turbine.

Thermal Efficiency: Turbocharging increases cylinder pressures and heat, forcing compromises in compression ratios and timing that NA engines don’t have to make.

Longevity: More boost means more stress on rods, pistons, and bearings. Even "reliable" turbo engines rarely last as long as their NA counterparts under hard use.

The best naturally aspirated engines (think iHonda’s F20C, BMW’s S65, Ferrari’s F140) achieve specific outputs rivaling turbo motors without forced induction. They do it through precision engineering, not boost masking.

See also:

The Displacement Disgrace: How Turbos Enable Downsizing Deception

Automakers love to tout "downsizing"—replacing larger NA engines with smaller turbocharged ones under the guise of efficiency. But this is often a shell game.

A 2.0L turbo four might match the peak horsepower of a 3.5L V6, but at what cost?

Real-world fuel economy is often worse because drivers must push the turbo into boost to access power. Turbo engines suffer more degradation over time, thanks to carbon buildup, heat soak, and oil coking plague direct-injection turbo motors in ways NA engines rarely experience.

The powerband is artificial. A turbo engine’s torque curve is shaped by boost thresholds, not mechanical harmony.

This is why so many "eco-friendly" turbo cars end up being disappointments. They trade the linear, predictable power of a well-designed NA engine for a peaky, inefficient mess that only looks good on paper.

The Reliability Lie: Boost Always Comes At A Cost

Turbo enthusiasts love to claim modern forced induction is "just as reliable" as NA. But physics disagrees. Here's why:

Increased Cylinder Pressures: More boost means more force on rods, pistons, and head gaskets. Even with advancements in metallurgy, this inevitably shortens engine life.

Heat Management Issues: Turbos generate extreme exhaust gas temperatures, cooking oil, degrading seals, and warping components over time.

Complexity: Every turbo system adds intercoolers, wastegates, blow-off valves, and oil feed lines. They're all potential failure points.

Show me a 300,000-mile turbo engine that hasn’t had major work. Now show me a dozen NA Toyota 2JZs, GM LS motors, or Honda K-series that hit that mileage on original internals.

The difference is obvious.

The Sound And Soul Problem: Turbos Muffle Mechanical Character

There’s a reason the greatest engine notes in history come from NA motors:

Ferrari’s F136 V8 screaming to 9,000 RPM. Porsche’s Mezger flat-six howling through individual throttle bodies. Lexus’ 1LR-GUE V10 wailing like a Formula 1 car.

Turbos act as mufflers, choking exhaust pulses and dulling the mechanical symphony of a great engine. Even the best turbo setups—Porsche’s 911 Turbo, the BMW S58—sound artificial compared to their NA counterparts.

The Future: A Call For Balanced Engineering

This isn’t to say turbos have no place. For certain applications (diesel trucks, hypercars chasing four-digit power), forced induction makes sense. But the industry’s wholesale abandonment of NA development in favor of turbo band-aids is a tragedy.

We need a return to holistic engine design, where power comes from intelligent combustion chamber design, optimized airflow, and high-revving mechanical precision, not just cranking up the boost.

The greatest engines in history were naturally aspirated. The future shouldn’t forget that.