In the race toward an all-electric future, automakers are in an arms race not just over batteries but over electric motors — the beating hearts of electric vehicles (EVs). For years, the industry has largely relied on two dominant motor types: permanent magnet synchronous motors (PMSMs) and induction motors. Both have matured, proven reliable, and scaled well.

But a new contender has quietly emerged from the shadows of niche engineering circles and prototype labs: the axial flux electric motor. Compact, lightweight, and incredibly power-dense, this design could reshape how EVs are engineered from the ground up. Some of the biggest names in performance and luxury — Ferrari, Mercedes-Benz, and Koenigsegg — have already begun betting on it.

The question is: can axial flux technology truly replace today’s dominant radial designs, or is it destined to remain a boutique solution for high-end vehicles?

What Exactly Is an Axial Flux Electric Motor?

To understand why engineers are excited, we need to start with the fundamentals.

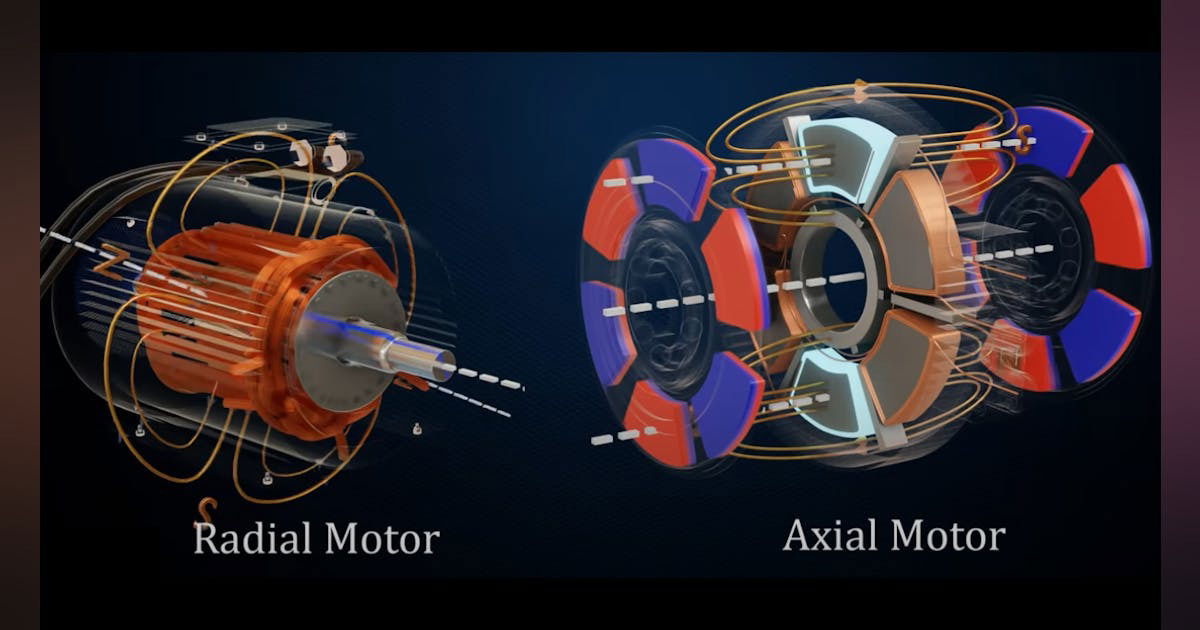

Traditional EV motors — the kind used by Tesla, Hyundai, or BYD — are typically radial flux motors. In these designs, the magnetic field flows radially outward from the rotor to the stator, and torque is generated along the circumference of the rotor. It’s a tried-and-true setup that works, but it has some physical limitations.

In contrast, an axial flux electric motor produces torque along the motor’s axis — meaning the magnetic field lines run parallel to the rotation shaft rather than outward. This “pancake” layout allows engineers to pack more torque into a smaller, lighter unit.

In essence:

Radial flux = cylinder-shaped, longer motor.

Axial flux = disk-shaped, flatter motor.

The result? Higher torque density and better efficiency, all in a form factor that can be integrated more flexibly within the vehicle's chassis or wheel hubs.

Axial Flux Motor Efficiency: The Physics of Doing More with Less

Efficiency is where the axial flux motor really shines. Because of its geometry, the motor can use a larger effective radius — where torque generation is most efficient — without adding much mass. This means more mechanical leverage from the same electromagnetic force.

Typical radial motors achieve efficiencies between 90% and 93%, depending on design and cooling. Meanwhile, axial flux motor efficiency can reach 95% or even higher in optimized configurations.

But the benefits don’t stop there. The shorter magnetic flux path reduces energy loss, and cooling is often simpler because the flat geometry allows for better thermal exposure to air or liquid systems.

In electric vehicles, where every percentage of efficiency translates into real-world range, this advantage is golden. An EV fitted with an axial flux motor could, in theory, achieve 5–10% longer range from the same battery pack — or deliver higher performance without sacrificing efficiency.

Axial Flux Motor vs Radial Flux Motor: The Showdown

Let’s break down the practical differences in the axial flux motor vs radial flux motor debate:

| Feature | Axial Flux Motor | Radial Flux Motor |

|---|---|---|

| Design Layout | Flat, disc-like (“pancake”) | Cylindrical, elongated |

| Torque Density | Very high — ideal for compact EVs or in-wheel setups | Moderate — limited by radius |

| Efficiency | Up to 95–97% | Typically 90–93% |

| Cooling | Easier surface cooling due to flat form | More complex internal cooling |

| Manufacturing Complexity | High — tight tolerances, precision assembly required | Mature and well-understood |

| Scalability | Still developing | Proven for mass production |

| Best Use Cases | Performance EVs, motorcycles, aerospace, in-wheel motors | Mainstream EVs and hybrids |

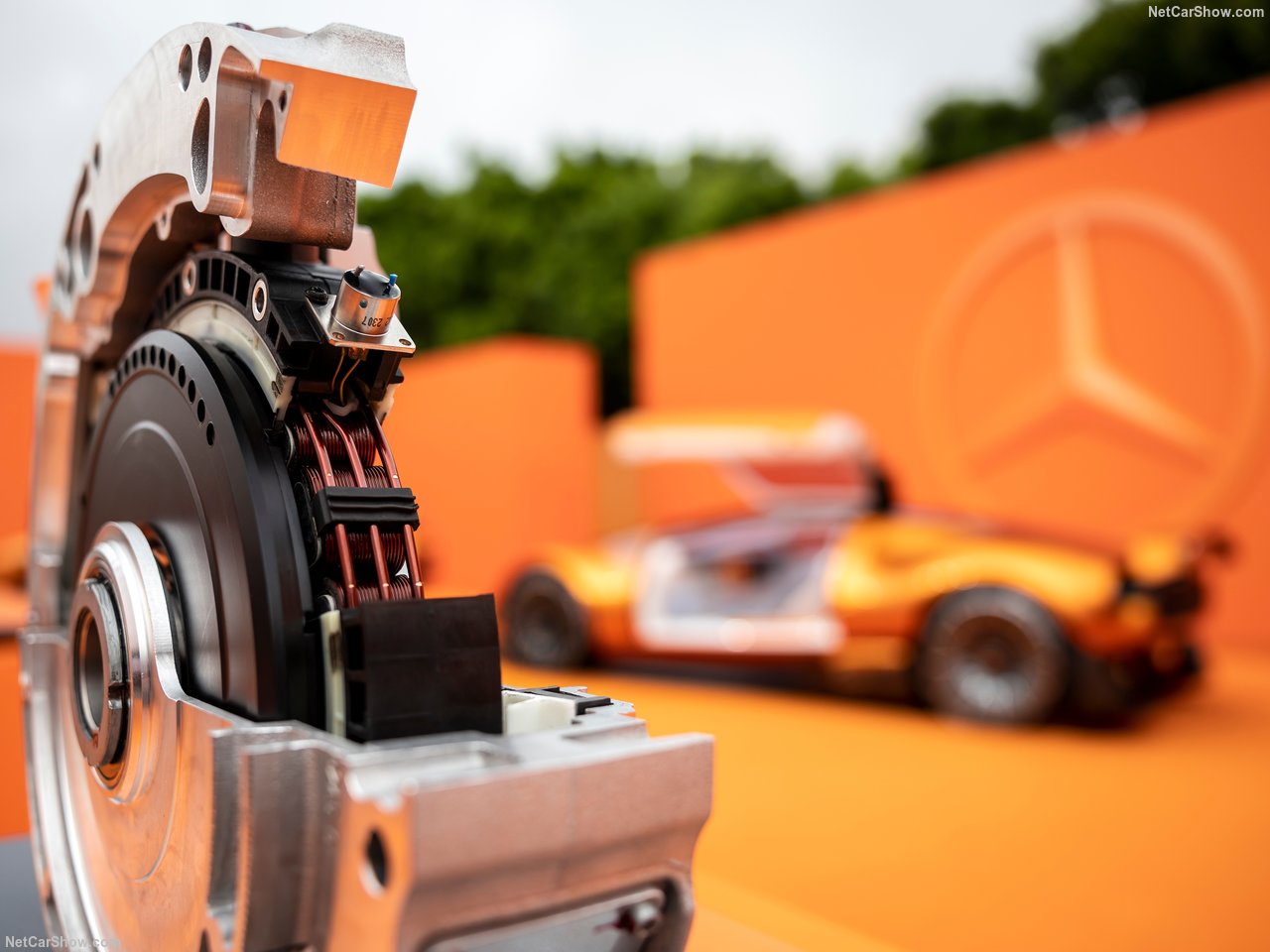

The axial flux design isn’t just theoretically better — it’s already proving itself in demanding real-world applications. For example, YASA, a British company acquired by Mercedes-Benz, has pioneered production-ready axial flux motors that power vehicles like the Ferrari SF90 Stradale and Mercedes-AMG S63 E Performance. These aren’t concept cars; they’re production models that demonstrate the technology’s real-world viability.

So, why are big automakers betting on Axial Flux motors?

Mercedes didn’t buy YASA for curiosity’s sake. It saw the strategic potential. Axial flux motors allow automakers to achieve more torque per kilogram — in some cases up to three times the torque density of conventional radial motors. That’s a game-changer for performance and packaging efficiency.

For example:

The YASA axial flux motor delivers 15 kW per kilogram, compared to about 5 kW/kg for typical radial flux motors. This means a smaller, lighter motor can deliver supercar-level performance while saving space for batteries or cooling systems.

It’s no wonder Mercedes plans to integrate YASA’s designs into its next-generation AMG EVs, while startups and aerospace companies eye similar designs for lightweight aircraft propulsion.

Axial Flux Motor Price: Why It’s Not Yet Mainstream

As promising as it is, the axial flux motor price remains a major obstacle to widespread adoption.

Precision manufacturing is costly. The tolerances in an axial flux motor are extremely tight, especially in the stator and rotor alignment. Any slight misalignment affects efficiency and cooling performance. Materials like high-grade silicon steel, advanced composite housings, and permanent magnets push costs up further.

While prices vary depending on design and volume, an axial flux motor can cost 30–50% more than an equivalent radial flux motor at current production scales.

To illustrate, the YASA axial flux motor price for high-performance applications is estimated around $4,000–$6,000 per unit, compared to about $2,000–$3,000 for comparable radial motors used in mass-market EVs.

However, these figures are changing rapidly. As production scales up and new manufacturing techniques — like 3D-printed stator components and automated winding — mature, the cost gap could narrow significantly over the next five years.

Engineering Challenges: Scaling the Pancake

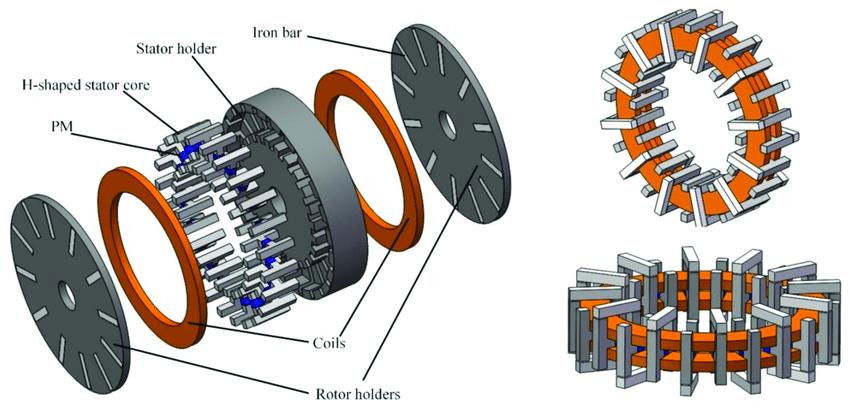

The physics of axial flux design are elegant, but manufacturing is anything but simple. Engineers face several key challenges:

1. Magnetic Force Management: The flat geometry means stronger axial magnetic attraction between stator and rotor, which can cause mechanical stress.

2. Cooling Uniformity: Flat surfaces cool well, but managing heat in the core or center region can be tricky.

3. Assembly Precision: The tight air gap (often <1mm) requires ultra-precise alignment to maintain performance.

4. Supply Chain: Advanced permanent magnets and specialized laminations aren’t yet produced at mass-market scales.

These factors contribute not just to axial flux motor price, but also to slower adoption in mainstream EVs. It’s one thing to hand-build motors for Ferrari; it’s another to mass-produce millions for compact SUVs.

Despite the challenges, the axial flux electric motor offers a new level of design flexibility that excites vehicle engineers. Because of its flat form, it can be mounted directly to the chassis, near the wheels, or even integrated into the drivetrain in unconventional ways.

Imagine an EV with four small axial flux motors — one in each wheel — each delivering precise torque independently. Such architectures promise incredible handling, instant torque vectoring, and redundancy for safety.

Lightweight electric motorcycles, drones, and even electric aircraft are also adopting the technology for its unmatched power-to-weight ratio. In short, axial flux motors aren’t just another incremental improvement — they open the door to entirely new EV architectures.

As the automotive industry grapples with sustainability goals, axial flux motor efficiency becomes even more valuable. Every gain in motor performance reduces the strain on batteries, allowing for smaller packs, less material use, and lower carbon footprints.

Moreover, YASA and other developers are exploring ways to reduce rare earth magnet dependency by experimenting with ferrite-based alternatives or novel composite materials. This could make axial flux designs not only efficient but also more environmentally sustainable than traditional motors.

The Coming Wave of Competition

YASA may be the most visible player, but it’s not alone. Companies like Magnax (Belgium), Saietta (UK), and EMRAX (Slovenia) are developing their own axial flux variants targeting everything from commercial vehicles to aircraft propulsion.

Magnax claims torque densities up to 20 Nm/kg, positioning itself as a rival to YASA for high-performance EVs. Saietta focuses on scalable, cost-efficient designs for scooters, small cars, and marine applications. EMRAX serves aerospace and industrial markets, proving the design’s flexibility.

A surge in competition will inevitably drive down the axial flux motor price, just as battery costs plummeted once mass production took off.

Who Wins: Axial Flux or Radial Flux?

In the short term, radial flux motors will continue to dominate mainstream EVs due to established supply chains and manufacturing know-how. But in the long term, the advantages of axial flux designs are too compelling to ignore.

As automakers push for lighter, faster, and more efficient EVs — and as axial flux motor efficiency and production economics improve — it’s likely we’ll see a hybrid landscape emerge:

Radial flux motors in affordable, mass-market vehicles.

Axial flux motors in performance, luxury, and high-efficiency platforms.

Eventually, as manufacturing scales, axial flux could become the standard architecture for electric propulsion — just as lithium-ion once replaced nickel-metal hydride.