Don't you just long for the golden age of simplicity? There was a time when opening the hood of a car meant seeing an engine—not a plastic shroud hiding a maze of sensors, wiring harnesses, and proprietary modules.

The 1990s marked the last great era of analog automobiles, where a decent set of tools, a Chilton manual, and some mechanical intuition were all you needed to keep your car running for decades.

Today, we’ve entered an age where cars are so overengineered, so needlessly complex, and so hostile to independent repair that they might as well be disposable appliances (disposable diapers work just fine). Modern vehicles are technological marvels on paper—packed with efficiency gains, cutting-edge safety, and infotainment systems that rival supercomputers.

But beneath the glossy touchscreens and adaptive cruise control lies a nightmare for mechanics. And enthusiasts. Cars today are designed to be leased, not owned; to be serviced by dealerships, not backyard wrenchers; and to fail just outside of warranty, ensuring a steady stream of revenue for manufacturers.

This is the death of the true "driver’s car," replaced by rolling computers that prioritize corporate profits over longevity, repairability, and driving purity. This is a justifiable rant about exactly why modern cars are overengineered garbage—and why we should bring back the simplicity of the 90s.

See also:

The Ungodly Rise Of The Unfixable Engine Bay

Pop the hood of a 1995 Honda Civic, and you’ll see an engine. A real, honest-to-God engine—with a distributor, a throttle cable, and fuel lines you can actually trace with your eyes.

Now, open the hood of a 2025 BMW 3 Series.

What do you see?

Plastic.

Layers upon layers of plastic covers, hiding an engine so tightly packed that changing a spark plug could probably leave you removing half the intake system.

Modern engines are engineering marvels, yes—but they’re also repair disasters. Turbochargers stuffed into tiny engine bays, direct injection systems that carbon up by 60,000 miles, and timing chains buried behind the firewall ensure that even basic maintenance is a dealer-only affair.

Take the Ford EcoBoost engines: brilliant in theory, but notorious for failing turbos, coolant intrusion, and carbon buildup that turns them into ticking time bombs.

In the 90s, a timing belt job was a weekend project. Today, it’s a $1,500 ordeal because the water pump is buried under the timing cover, requiring the entire front of the engine to be disassembled. This isn’t progress—it’s planned obsolescence disguised as innovation.

The Death Of The Shade Tree Mechanic

There was a time when a motivated amateur could rebuild an engine in their driveway with a Haynes manual and some borrowed tools. Today? Forget it.

Modern cars are so reliant on proprietary software, encrypted modules, and dealer-only programming that even a simple battery replacement can require a trip to the dealership.

Take the case of GM’s "Theft Deterrent System," which you can only be thankful it doesn’t brick your car’s ECU if you don’t perform a 30-minute "relearn procedure" after disconnecting the battery. Or BMW’s insistence on coding new batteries to the car, turning a $150 DIY job into a $400 dealer visit.

Even changing a headlight bulb now often requires removing the front bumper—because why make anything accessible?

The right-to-repair movement is fighting back, but manufacturers are winning. They’ve turned cars into black boxes, where even independent shops struggle to keep up with the constant software updates and encrypted diagnostics.

The result?

A monopoly on repairs, skyrocketing maintenance costs, and a generation of car owners who feel like morons and are completely at the mercy of dealership service departments.

The Sensor Apocalypse

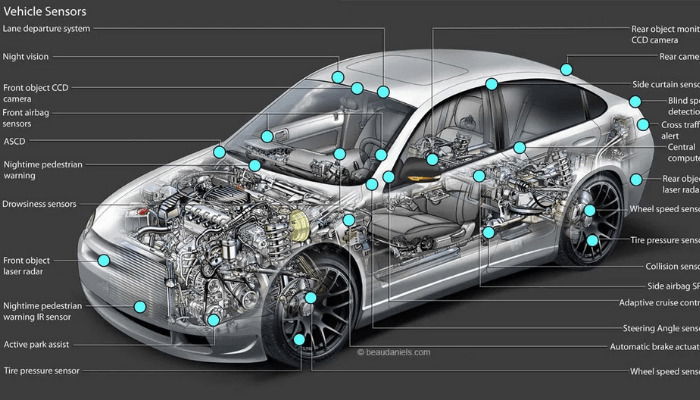

Modern cars are drowning in sensors. Oxygen sensors, mass airflow sensors, cam position sensors, tire pressure sensors, rain sensors, seat occupancy sensors—the list goes on. In theory, these make cars more efficient and safer. In reality, they turn every minor issue into a cascading electrical nightmare.

A 90s OBD-I car would throw a check engine light for a real problem—a misfire, a vacuum leak, a bad oxygen sensor. Today’s OBD-II systems will freak out over a slightly loose gas cap, a weak battery, or a "ghost code" caused by a glitch in the CAN bus network.

And God help you if your car has a failing wheel speed sensor—it might disable your ABS, traction control, and even your power steering as a "safety precaution."

Worse yet, these sensors are designed to fail. Modern oxygen sensors, for example, have a finite lifespan—usually around 100,000 miles. When they go bad, your fuel economy tanks, and your car runs like garbage.

But instead of a simple $50 replacement like in the old days, you now have to deal with upstream and downstream sensors, often buried under heat shields and exhaust components.

See also:

Dave from Atlanta

Dave loved his 2018 BMW 328i (F30 chassis) sedan—until the sensors turned on him.

Not Dave's actual car.

It started with a flickering tire pressure light. No big deal, he thought. The tires were fine. But the car didn’t care. It crippled the stability control "for safety." The steering now felt like a shopping cart with a stuck wheel.

Then the rain sensor joined the revolt. A speck of pollen (Dave suspects) tricked it into thinking a monsoon was coming, so the wipers started slapping dry glass at highway speed. The infotainment screen flashed a warning: "WIPER FAILURE—SEE DEALER."

The final blow came at rush hour. A failing cam position sensor—buried under a labyrinth of plastic covers—made the engine stutter. The dashboard lit up like a Christmas tree: "REDUCED POWER. TRACTION CONTROL OFF. EMISSIONS SYSTEM FAULT." The car limped home at 25 mph, guzzling gas like a '70s land yacht.

That night, Dave dug out the keys to his old '96 pickup. It had one sensor for the check engine light—and it only came on when something actually broke.

The next morning, he drove past the dealership’s service bay, where his sedan sat waiting for a $1,200 "diagnosis." He smiled, rolled down the window (manually), and let the V6 roar. Some lessons are best learned the hard way.

The Disposable Car Mentality

1990s Toyota RAV4 vs. modern RAV4.

Cars used to be built to last. A well-maintained 90s Toyota or Honda could easily hit 300,000 miles with basic care. Today? Many modern engines are lucky to see 150,000 before major failures. Why? Because manufacturers have shifted from "build it to last" to "build it to survive the warranty period."

Take Hyundai/Kia’s Theta II engine debacle—thousands of engines failing due to poor manufacturing, leading to class-action lawsuits. Or Chrysler’s infamous 2.4L "World Engine," known for eating its own timing chains before 80,000 miles.

Even "reliable" brands like Toyota have fallen victim to this trend, with newer models suffering from oil consumption issues, CVT failures, and hybrid battery degradation. The problem isn’t just bad engineering.

Are we wrong to call it intentional design? Cars are now filled with plastic coolant fittings, cheap aluminum bolts, and fragile wiring harnesses that degrade over time. How can it not be clear that the goal is to ensure the car becomes uneconomical to repair, pushing the owner into a new lease?

The Touchscreen Takeover (And Why It Sucks)

Remember when cars had buttons? Real, tactile buttons that you could press without taking your eyes off the road? Those days are gone, replaced by laggy, fingerprint-smudged touchscreens that control everything from the A/C to the suspension settings.

Tesla started this trend.

And now every manufacturer is following suit. The result? A distracted driving epidemic, where simple tasks like adjusting the fan speed require navigating through three submenus. Even worse, when these screens fail (and they do), you lose access to critical functions—like your defroster or backup camera.

But the real crime is that these systems are impossible to fix yourself. A broken infotainment screen in a modern car can cost thousands to replace, often requiring dealer programming to even work. In the 90s, if your radio died, you went to Best Buy and slapped in a new one. Today? You’re at the mercy of the manufacturer.

Ah, The Good Ol' Days: 1990s Cars You Can Actually Fix

The 1990s marked the end of an era.

Toyota’s 22RE is the gold standard of no-nonsense reliability. Found in Pickups and 4Runners from the late '80s through the mid-'90s, this 2.4L fuel-injected four-cylinder was tough as nails, with a timing chain that rarely failed and a design so straightforward that a backyard mechanic could rebuild it over a weekend. It wasn’t fast, but it refused to die—the perfect companion for anyone who valued function over flash.

Honda’s D-series engines, powering Civics, CRXs, and Del Sols, were masters of efficiency and simplicity. The 1.5L and 1.6L D15 and D16 mills were non-interference, meaning a snapped timing belt wouldn’t destroy the engine, and their compact design made maintenance a breeze. Even better, they sipped fuel while delivering 40+ MPG.

Drivers who craved torque without complexity found true solace in Ford’s 300 cubic-inch (4.9L) inline-six. Used in F-150s and Broncos up until 1996, this engine was essentially a tractor motor stuffed under a hood—carbureted or with rudimentary EFI, devoid of unnecessary electronics, and capable of running on fumes and willpower alone. It wasn’t glamorous, but it outlasted most of its owners.

Chevrolet’s small-block 350 V8, found in GMT400 trucks and the Caprice, kept things refreshingly simple even as the industry marched toward complexity. With throttle-body or Vortec injection, no timing belt to worry about, and a vast aftermarket, this engine was a dream for DIY mechanics. Need more power? A cam swap and headers could wake it up without ever needing a laptop.

Jeep’s 4.0L straight-six, powering Cherokees and Wranglers, was another legend. This engine had just enough EFI to be reliable but none of the overcomplications of modern powerplants. It made gobs of low-end torque, laughed at neglect, and could be fixed with a hammer, a wrench, and some creative language.

Volvo’s redblock B230, found in 240s, 740s, and 940s, was Sweden’s gift to no-fuss motoring. Cast-iron tough, either with primitive K-Jetronic injection or later LH-Jetronic systems, this engine didn’t care about mileage—it just kept running. Turbo versions could make serious power without sacrificing reliability.

Nissan’s KA24DE, used in the Hardbody pickup and 240SX, was a no-nonsense four-cylinder with a timing chain, non-interference design, and enough durability to handle abuse. It wasn’t flashy, but it got the job done—and in the 240SX, it became a drift icon precisely because it was so simple to modify and maintain.

Mazda’s little B-series engines, particularly the 1.6L and 1.8L in Miatas, were proof that simplicity and fun could go hand in hand. These rev-happy, lightweight powerplants were a joy to work on, with plenty of room in the engine bay and no unnecessary complexity. The B2200 pickup’s 2.2L was equally rugged, if not exciting—just another example of '90s no-frills engineering.

Beyond these, a few honorable mentions deserve recognition. Mercedes’ OM617 diesel was a tank, with mechanical injection that scoffed at electronics. Subaru’s EJ22 was a non-interference boxer that avoided the turbocharged headaches of its siblings. And GM’s 3800 V6, while boring, was so reliable and easy to fix that it became the default choice for anyone who just wanted a car that worked.

Today’s cars might be faster, safer, and more efficient, but they’ve lost something irreplaceable: the ability to be truly owned, understood, and repaired by the person behind the wheel. If you want a car that respects your time, your wallet, and your independence, the '90s are where it’s at.

The Last Rant: Bring Back The 90s

'90s Toyota Tacoma with the 22RE engine.

Modern cars are faster, safer, and more efficient than ever. But they’re also needlessly complex, unreliable long-term, and hostile to anyone who dares to work on them outside a dealership.

The automotive industry has sacrificed repairability, durability, and driving enjoyment at the altar of planned obsolescence and corporate profits. We need a return to simplicity. Not necessarily a rejection of all technology, but a rejection of overengineering for the sake of locking out independent repair.

We need cars that can be fixed with basic tools, that don’t require a software engineering degree to diagnose, and that are built to last—not just to survive a lease term. The 90s proved that cars could be both advanced and serviceable.

It’s time to demand that balance again. Because right now, we’re heading toward a future where car ownership is dead—replaced by subscription-based transportation where you own nothing and the manufacturer controls everything. And that’s not a future any real car enthusiast should accept.